![]()

Marine environments are among the most punishing operating conditions for mechanical and fluid-transfer systems. From constant saltwater exposure to extreme temperature fluctuations and relentless vibration, hoses used in marine applications must perform reliably where standard materials often fail. Selecting superior hose materials is not simply a matter of longevity, it is critical to safety, efficiency and compliance.

The Unique Challenges of Marine Environments

Marine systems operate under a combination of stressors rarely found in other industries. Saltwater, humidity, UV radiation, fuel exposure and confined engine spaces create an environment where material degradation accelerates rapidly.

Key environmental pressures include:

• Saltwater corrosion: Salt acts as a catalyst for material breakdown, particularly in inferior rubber compounds.

• Temperature extremes: Marine engines generate intense heat, while external conditions can swing dramatically.

• Constant vibration and movement: Wave action and engine operation place continuous mechanical stress on hoses.

• Chemical exposure: Fuels, oils, coolants and cleaning agents can attack low-grade hose materials.

Inadequate hose selection in these conditions can lead to swelling, cracking, delamination or catastrophic failure.

Why Standard Hose Materials Fall Short

Conventional rubber hoses, often designed for automotive or light industrial use, are not engineered to withstand prolonged marine exposure. Over time, they may suffer from:

• Premature hardening or softening

• Loss of pressure resistance

• Surface cracking from UV exposure

• Internal breakdown when exposed to fuel blends or saltwater vapour

These failures increase maintenance costs and elevate the risk of system downtime or environmental hazards.

The Importance of Superior Hose Materials

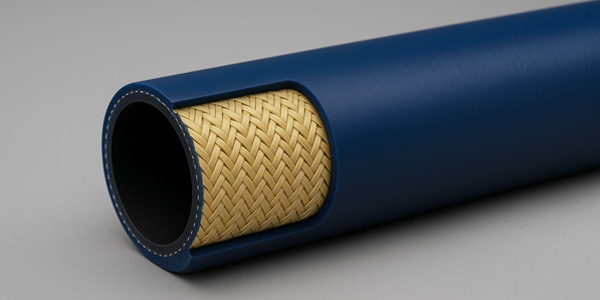

High-performance marine hoses are purpose-built to resist the specific challenges of maritime use. Materials such as marine-grade silicone, reinforced EPDM and fluoro-lined hoses offer significant advantages.

Key Performance Benefits

• Enhanced corrosion resistance: Superior compounds resist salt-induced degradation.

• Thermal stability: Maintains flexibility and strength across a wide temperature range.

• Chemical compatibility: Withstands exposure to fuels, oils, and coolants.

• Extended service life: Reduced cracking, swelling, and fatigue over time.

• Improved safety: Lower risk of leaks, bursts or system failure.

These properties are essential for critical systems such as cooling circuits, exhaust systems, fuel delivery and bilge operations.

Silicone Hoses in Marine Applications

Marine-grade silicone hoses have become increasingly popular due to their exceptional durability and performance consistency. Unlike traditional rubber, silicone maintains its flexibility under high heat and resists UV and ozone damage, two major contributors to hose failure in exposed marine environments.

Common marine uses include:

• Engine coolant hoses

• Turbocharger and intake systems

• Wet and dry exhaust connections

• Auxiliary fluid transfer lines

When reinforced correctly, silicone hoses also offer excellent pressure handling and vibration resistance.

Compliance, Reliability and Long-Term Value

Marine vessels, whether commercial or recreational, must meet stringent safety and regulatory standards. Hose failure can result in costly repairs, operational downtime, or regulatory non-compliance. Investing in superior hose materials reduces long-term maintenance costs and enhances operational reliability.

From offshore platforms to leisure craft, the choice of hose material directly impacts performance, safety and lifecycle value.

Final Thoughts

Marine environments leave no margin for material weakness. The combination of saltwater, heat, chemicals and mechanical stress demands hose solutions engineered specifically for these conditions. Superior hose materials are not an upgrade; they are a necessity.