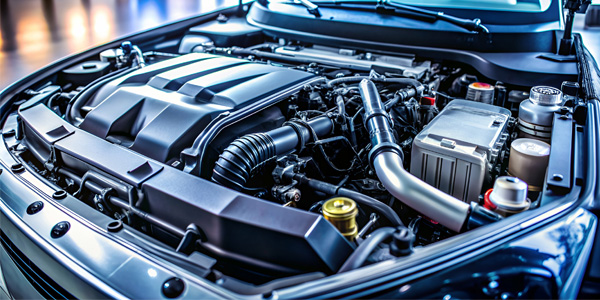

When it comes to high-pressure systems, every component matters — and aluminium joiners are no exception. These lightweight yet incredibly strong connectors play a crucial role in maintaining system integrity, performance, and safety. Whether you’re building a custom turbo setup, enhancing a race car, or designing industrial piping, aluminium joiners provide the durability and precision needed for high-pressure environments.

Why Aluminium?

Aluminium is the material of choice for joiners in high-pressure systems for several key reasons:

- Lightweight Strength: Aluminium offers a high strength-to-weight ratio, which is ideal for applications where reducing weight is critical, such as motorsports and aerospace.

- Corrosion Resistance: Especially when anodised, aluminium resists corrosion even when exposed to moisture, oil, and extreme temperatures.

- Thermal Conductivity: It helps dissipate heat efficiently, which is essential in systems involving compressed air or fluids.

- Ease of Fabrication: Aluminium can be machined, welded, or shaped with relative ease, allowing for custom setups and seamless installation.

Key Applications in High-Pressure Systems

Aluminium joiners are used in a wide range of systems, including:

- Turbo and Intercooler Piping: Connecting components in high-boost environments where pressure can exceed 30 PSI.

- Radiator and Coolant Systems: Withstanding pressure and temperature fluctuations without deforming.

- Oil and Fuel Systems: Providing a secure seal that prevents leaks under pressure.

- Industrial Pneumatics: Handling compressed air lines in automation and manufacturing equipment.

Choosing the Right Aluminium Joiner

Not all aluminium joiners are created equal. Here’s what to look for when selecting the right one:

- Wall Thickness: Thicker walls offer more strength but add weight; the ideal thickness balances both.

- Diameter Compatibility: Ensure a snug fit with silicone hoses, clamps or adjoining pipes.

- Finish: A smooth or anodised finish not only looks professional but also adds extra resistance to corrosion.

- Manufacturing Quality: Look for precision welds, clean edges and consistent measurements to ensure long-term reliability.

Benefits of Using Aluminium Joiners

- Enhanced Pressure Tolerance: Aluminium’s rigidity prevents flex and collapse under high pressure.

- Improved Longevity: Less wear and tear compared to plastic or rubber alternatives.

- Customisation Options: Easily cut, bent or welded to suit unique system layouts.

Conclusion

In high-pressure systems, reliability is non-negotiable and aluminium joiners deliver just that. Their strength, resistance and lightweight design make them a preferred choice for engineers, mechanics and performance enthusiasts alike. Whether you’re upgrading a vehicle’s forced induction setup or managing industrial fluid flow, investing in quality aluminium joiners ensures your system runs safely and efficiently under pressure.