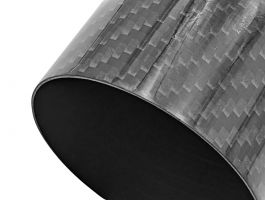

Carbon fibre pipes are typically manufactured using a process called filament winding. Here are the detailed steps involved:

Preparing the mandrel: A mandrel, which is a cylindrical tool, is prepared with the required dimensions and shape for the carbon fibre pipe. It is made of materials such as aluminium, steel or plastic and is usually coated with a release agent to prevent the pipe from sticking to it.

Preparing the carbon fibre: The carbon fibre is typically in the form of a woven fabric or unidirectional tow. The fibres are impregnated with a resin, usually epoxy, which is mixed with a hardener to form a tough, durable composite material.

Filament winding: The impregnated carbon fibre is wound around the mandrel in a specific pattern using a filament winding machine. The machine rotates the mandrel while a filament winding head guides the carbon fibre onto the mandrel. The winding pattern is chosen based on the required properties of the finished pipe, such as strength, stiffness, and durability.

Curing: Once the desired number of layers of carbon fibre has been wound onto the mandrel, the pipe is heated to cure the resin. The curing process is typically done in an oven or autoclave, depending on the specific resin used. The heat and pressure applied during the curing process help to bond the fibres and resin together, creating a strong, durable composite material.

Finishing: Once the curing process is complete, the carbon fibre pipe is removed from the mandrel. It may then undergo additional finishing processes such as sanding or polishing to achieve the desired surface finish. The ends of the pipe may also be trimmed or machined to the required dimensions.

Quality control: The finished carbon fibre pipe is inspected for defects and undergoes testing to ensure it meets the required specifications for strength, stiffness, and durability.

Overall, carbon fibre pipes are made using a precise and controlled manufacturing process to ensure high-quality, consistent performance.